Systematics for Determining Mohs Hardness

The hardness of minerals is mainly indicated using the Mohs scale, but there are also other systems, such as the grinding hardness according to Rosiwal or the microhardness according to Vickers.

The Mohs hardness is named after the inventor of the associated testing method, Friedrich Mohs, who lived from 1773 to 1839. He determined the Mohs hardness of various known minerals by scratching each other. He used a simple basic rule according to which the harder object scratches the softer one. If no scratched mark is left on the object to be tested, the test material is the harder one. If two media cannot be scratched against each other, then they have the same Mohs hardness.

Mohs hardness – a scale from 1 to 10

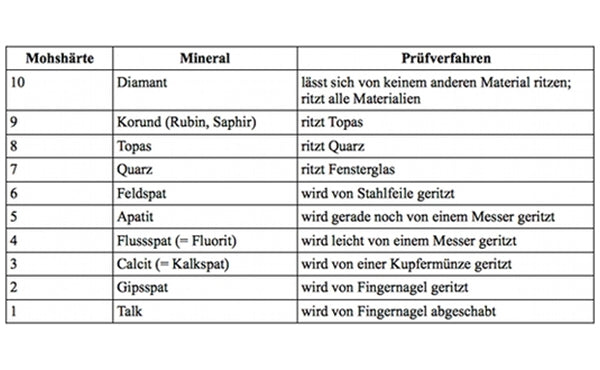

In terms of Mohs hardness, known minerals are assigned values between 1 and 10, which can be used to determine the Mohs hardness of the remaining substances. It should be noted, however, that the Mohs hardness scale is not linear - the differences in hardness between two minerals that are, for example, three points apart do not necessarily have to be the same.

A Mohs hardness of 10 is assigned to diamond , the hardest material. This is why the diamond can only be cut with the help of another diamond.

The diamond is closely followed by the corundum group, which includes rubies and sapphires .

Friedrich Mohs assigned the Mohs hardness 1 to talc.

It should be noted that minerals often have a lower hardness on surfaces that run parallel to the crystal structure than on those that run perpendicular to it.